23

2024

-

01

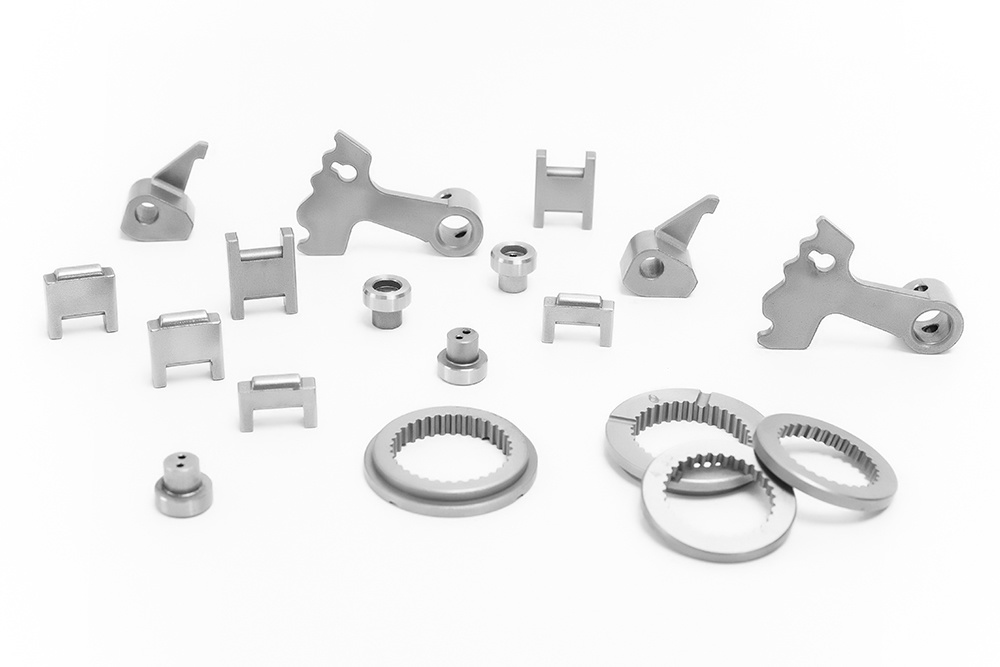

How to realize the high precision manufacturing of powder metallurgy parts

Author:

To achieve high-precision manufacturing of powder metallurgy parts, the following aspects can be considered:

1. Powder selection and preparation: Select powder raw materials with high purity and uniform particle size, and adopt appropriate powder preparation methods to ensure the quality and consistency of the powder.

2. Mold design and manufacturing: carefully design the mold, taking into account the shrinkage rate, demoulding angle and other factors to ensure the dimensional accuracy of the parts. Use high-precision processing equipment and technology to manufacture molds.

3. Pressing process control: control the pressure, temperature and time and other parameters in the pressing process to obtain uniform density and dimensional accuracy. Adopt advanced pressing equipment and processes, such as isostatic pressing, hot isostatic pressing, etc.

4. Sintering process optimization: Optimize sintering parameters, such as temperature, time and atmosphere, to control the shrinkage and deformation of parts and improve accuracy. Select the appropriate sintering furnace and control system.

5. Post-treatment process: Use appropriate post-treatment processes, such as shaping, grinding, polishing, etc., to further improve the accuracy and surface quality of the parts.

6. Quality inspection and control: Implement strict quality inspection and control measures, including inspection and measurement, to ensure that the parts meet the accuracy requirements. Establish a quality management system to continuously improve the production process.

7. Technological innovation and cooperation: Continuously carry out technological innovation, explore new powder metallurgy technologies and processes, and cooperate with experts and institutions in related fields to jointly promote the development of high-precision manufacturing.

News

2024-01-23

Introduction of standard parts

2024-01-23

2024-01-23

Introduction of car synchronizer

2024-01-23

SAF Coolest v1.3.1.2 设置面板 QOYSX-AYJG-ASZAE-XQS

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page